In the ever-evolving landscape of electrical energy distribution, choosing the appropriate dry type power transformer is a critical decision for both industrial and commercial applications. According to a recent market analysis by Research and Markets, the global dry type transformer market is projected to reach USD 12 billion by 2027, reflecting a Compound Annual Growth Rate (CAGR) of 5.8% from 2022. This growth is fueled by increasing investments in renewable energy sources and the rising demand for energy efficiency in transformer design, underscoring the importance of making informed choices when selecting a dry type power transformer.

Dr. Emily Chen, a leading expert in electrical engineering and a recognized authority on transformer technologies, notes, “The right dry type power transformer can significantly enhance energy efficiency and reliability, ultimately reducing operational costs.” Her insight emphasizes the necessity for industry professionals to carefully evaluate their specific needs, taking into account factors such as application environment, load capacity, and maintenance requirements. By addressing these considerations, stakeholders can ensure optimal performance and longevity from their dry type power transformers, aligning with the broader goals of sustainable energy practices and technological advancements.

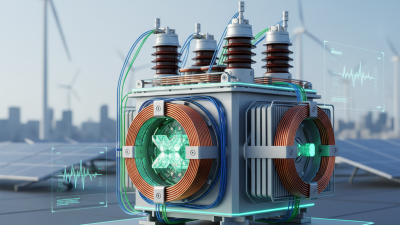

Dry type power transformers have become increasingly significant in modern electrical systems due to their numerous advantages over traditional liquid-filled transformers. These transformers use air as a cooling medium, which not only enhances their safety and efficiency but also allows for operation in a wider range of environmental conditions. According to a report by the International Energy Agency (IEA), dry type transformers accounted for approximately 40% of the transformer market share in 2022, underscoring their growing acceptance in various sectors including commercial, industrial, and renewable energy applications.

The importance of dry type transformers also lies in their reduced environmental impact. They are less prone to leaks and do not pose the risks associated with insulating oils, which can be detrimental to the environment. Research from the Electric Power Research Institute (EPRI) indicates that the adoption of dry type transformers can lead to a decrease in maintenance costs by up to 30%, providing both economic and ecological benefits. Additionally, these transformers can operate effectively in urban settings, reducing the risk of fire hazards and offering improved reliability in densely populated areas. As such, understanding the operational principles and key benefits of dry type power transformers is crucial for industries aiming to enhance their power infrastructure while prioritizing sustainability.

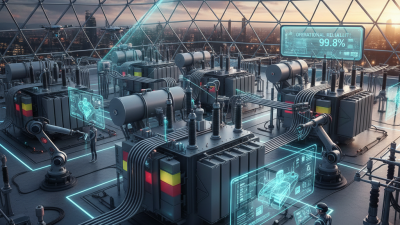

When selecting a dry type power transformer, several key factors must be taken into account to ensure that it meets your specific needs. First and foremost, the power rating is crucial. This involves understanding the voltage and current requirements of your application. Transformer's capacity should align with the total load it will support, allowing for any future expansions without risking overload. Additionally, consider the operating environment. Dry type transformers are designed for various settings, including indoors, outdoors, and harsh environments. Therefore, the ambient conditions such as temperature, humidity, and potential exposure to contaminants should be evaluated.

Another significant factor is efficiency and thermal management. Dry type transformers have better heat dissipation compared to liquid-filled types, making them suitable for areas where fire safety is a priority. However, it's essential to assess their efficiency ratings and cooling mechanisms. Also, pay attention to regulatory compliance and safety standards relevant to your installation location, as these can influence the type of transformer you select. Lastly, look into the maintenance requirements and lifespan of the transformer, since some designs might require more frequent checks, which can impact long-term operational costs.

When selecting the right dry type power transformer, understanding your load requirements is paramount. Load capacity, which is essentially the electrical demand at any given time, directly influences your choice of transformer. According to the International Electrotechnical Commission (IEC) standards, transformers should be selected based on continuous load measurements, peak demands, and future expansion plans. The general guideline is to choose a transformer that exceeds the estimated load requirement by 10-20%, ensuring reliability and longevity.

Moreover, different load types—resistive, inductive, or capacitive—impact transformer selection significantly. For instance, inductive loads typically require transformers with a higher inrush current capability, as highlighted in the IEEE Power and Energy Society's reports, indicating that loading conditions can shift dramatically depending on the equipment used (motors, generators, etc.). By analyzing your specific load profile, including starting currents and operational cycles, you can better determine the kVA rating necessary to accommodate your needs effectively, ensuring optimal performance and efficiency in your electrical system.

When selecting a dry type power transformer, evaluating the cooling methods is crucial for ensuring efficiency and longevity. Dry type transformers can utilize several cooling methods, such as air cooling, resin encapsulation, or natural convection. The choice of cooling method directly impacts the transformer's performance in different environmental conditions. According to a report from the International Electrotechnical Commission (IEC), natural air-cooled transformers can operate effectively within a temperature range of -25°C to +40°C, making them suitable for a wide variety of applications. In environments with higher ambient temperatures, using forced air cooling or oil-based designs can enhance thermal performance, thereby extending the lifespan of the transformer.

Environmental considerations further influence the decision-making process. Dry type transformers are favored for their lower environmental impact, as they do not use oil that can leak and cause contamination. The U.S. Department of Energy highlights that transformers employing advanced cooling methods such as vacuum pressure impregnation (VPI) significantly reduce the risk of moisture absorption and improve operational reliability. Additionally, using eco-friendly insulating materials can enhance the environmental sustainability of dry type transformers. This emphasis on cooling efficiency and environmental impact not only aids in selecting the appropriate transformer but also aligns with global efforts to reduce carbon footprints and promote energy conservation in electrical infrastructures.

When selecting a dry type power transformer, understanding safety standards and compliance is crucial. Dry type transformers are preferred in many applications due to their safety features, as they do not use flammable liquids for cooling. They must meet specific national and international safety standards, such as those set by the National Electrical Manufacturers Association (NEMA) and the Institute of Electrical and Electronics Engineers (IEEE). These organizations outline performance criteria and testing methods to ensure transformers are reliable, efficient, and safe for use.

Compliance with safety standards ensures that the transformer can withstand environmental factors, reducing the risk of electrical hazards or failures. Key considerations include insulation class ratings, temperature rise limits, and dielectric strength. Additionally, adherence to standards helps in identifying the appropriate installation practices, maintenance guidelines, and operational limits, which are essential in preventing accidents and ensuring longevity. Therefore, before making a purchase, it's essential to verify that the transformer complies with the relevant safety standards applicable in your region or industry, ensuring not only regulatory compliance but also the overall safety of your electrical systems.