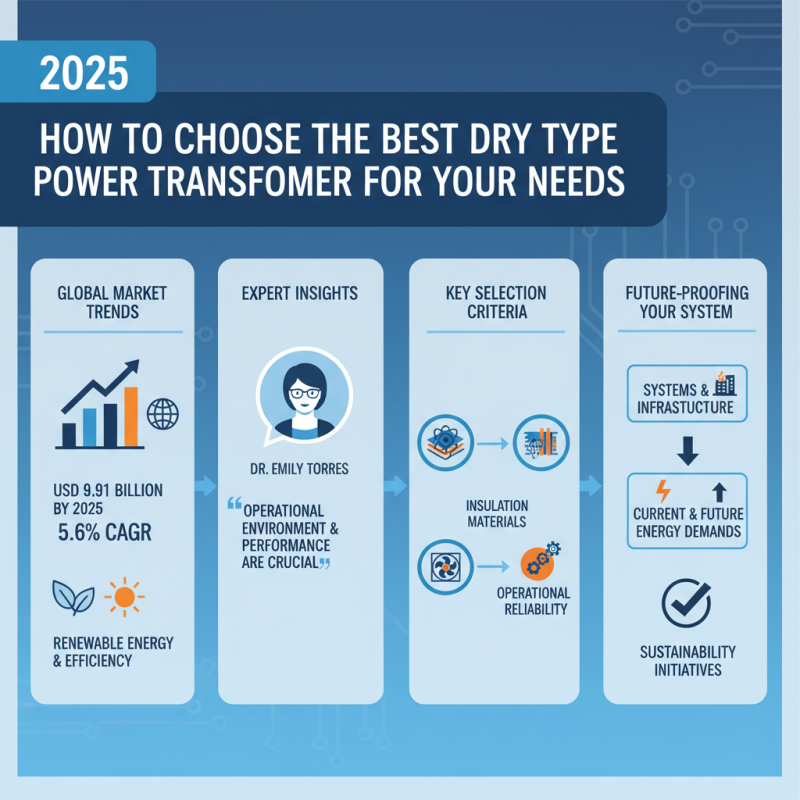

In the fast-evolving landscape of electrical engineering, the demand for efficient and reliable power solutions has never been greater. Among the various options available, the dry type power transformer stands out for its robust performance and environmentally friendly characteristics. According to a recent market report by Grand View Research, the global dry type transformer market is expected to reach USD 9.91 billion by 2025, reflecting an annual growth rate of 5.6%. This surge is driven by an increasing focus on energy efficiency and the rising adoption of renewable energy sources.

Experts in the field, such as Dr. Emily Torres, a prominent figure in transformer technology, emphasize the importance of selecting the right transformer for specific applications. "When selecting a dry type power transformer, understanding the operational environment and performance requirements is crucial for optimizing efficiency and prolonging service life," she states. The considerations for choosing the best dry type power transformer include aspects such as insulation materials, cooling methods, and overall operational reliability, all of which can significantly impact both performance and cost-effectiveness in the long run.

As we delve into the intricacies of selecting the most suitable dry type power transformer for your needs, it is essential to evaluate factors within your systems and infrastructure, ensuring that your choice aligns with both current and future energy demands. By comprehensively analyzing these criteria, stakeholders can secure a transformer that not only meets their technical requirements but also supports sustainability initiatives in the electrical network.

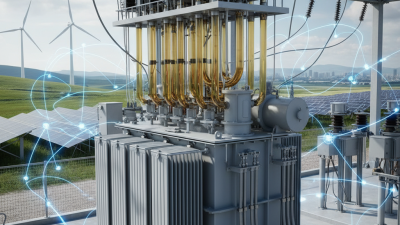

Dry type power transformers are crucial components in the electrical distribution system, functioning without the use of liquid insulation. Instead, they utilize air or solid insulation, which makes them a safer and more environmentally friendly option. These transformers are typically used in urban areas, indoor installations, and locations where fire hazards are a concern, as they significantly reduce the risk of fire due to the absence of flammable oils.

One of the primary advantages of dry type transformers is their lower maintenance requirements compared to their oil-filled counterparts. Their design allows for easier cooling and better management of thermal conditions. Additionally, dry type transformers are more resilient to environmental factors such as moisture and dirt, making them suitable for harsh conditions.

Understanding the operational principles and various configurations of dry type transformers is essential for selecting the right model to meet specific application needs, including factors such as power capacity, voltage ratings, and installation environment.

When selecting a dry type power transformer, several key factors must be considered to ensure it meets the specific requirements of your application. One crucial aspect is the transformer’s capacity, which is typically measured in kilovolt-amperes (kVA). The capacity should align with the anticipated load, which may increase or decrease based on the operational needs of the facility. According to a report by the International Electrotechnical Commission (IEC), properly sizing transformers can enhance efficiency by up to 20%, significantly reducing operational costs over time.

Another essential factor is the environment in which the transformer will be installed.

Dry type transformers are particularly advantageous in indoor or sensitive environments due to their robust insulation system and lower fire risk compared to oil-filled models. Assessing ambient temperature, humidity levels, and potential exposure to contaminants can influence both the selection and long-term performance. The Electrotechnical Commission suggests that transformers exposed to harsh conditions may require specialized protection features to prolong their lifespan and ensure reliability, leading to reduced maintenance expenses and downtime.

Lastly, energy efficiency is becoming increasingly important, driven by global initiatives advocating for sustainability. The U.S. Department of Energy reports that upgrading to high-efficiency dry type transformers can lead to energy savings of 3-5% annually, further contributing to reduced greenhouse gas emissions. Therefore, when selecting a transformer, evaluating its energy efficiency rating, alongside capacity and environmental considerations, is crucial for making an informed choice that aligns with both economic and ecological objectives.

When selecting a dry type power transformer, evaluating power ratings and load requirements is crucial for ensuring optimal performance and longevity. Power transformers are typically rated in kilovolt-amperes (kVA), and this rating indicates the maximum continuous power the transformer can handle under specific conditions. According to the IEEE, understanding the expected load conditions—such as load types, fluctuation, and peak demands—enables users to select a transformer that not only meets current needs but also accommodates future expansions. A standard practice suggests oversizing the transformer by 10-20% to prevent overloads caused by unanticipated growth in power demand.

In addition to power ratings, assessing the load characteristics specific to the application is essential. Different industries have distinct loading profiles; for example, a manufacturing facility may experience high inrush currents during equipment start-ups, while a data center will have a consistent and stable load. The National Electrical Manufacturers Association (NEMA) recommends considering the efficiency ratings and loss profiles of transformers to ensure energy consumption aligns with operational needs. For instance, using a transformer with a low core loss can significantly reduce operational costs over the transformer's lifespan, which can often exceed 30 years when properly maintained. Thus, a comprehensive evaluation of both power ratings and load requirements is indispensable in the selection process, ensuring reliability and efficiency in power delivery.

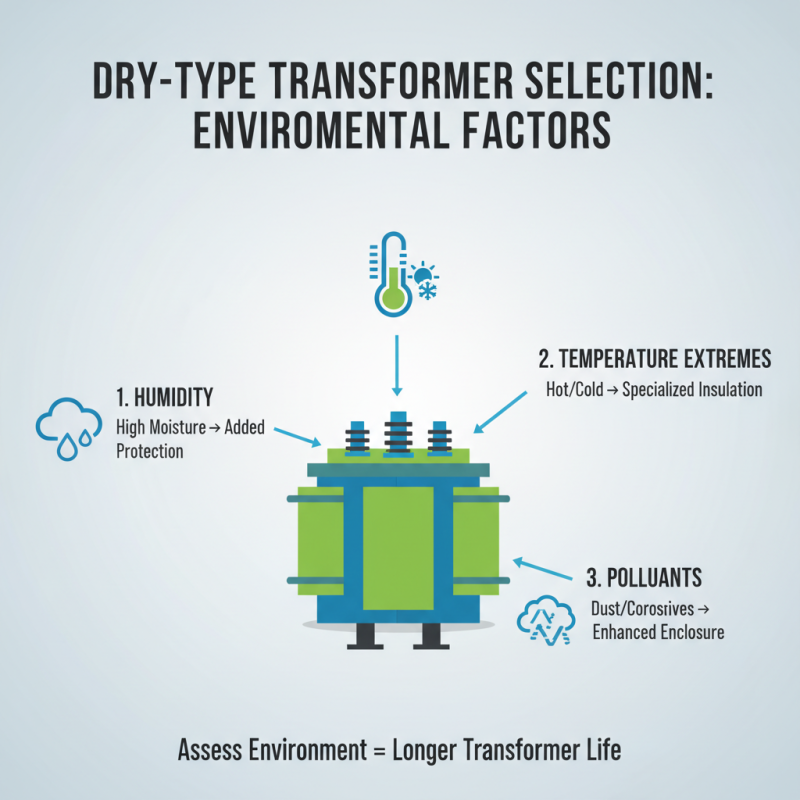

When selecting a dry type power transformer, it's crucial to assess the environmental conditions in which the transformer will operate. Factors such as humidity, temperature extremes, and exposure to pollutants can significantly affect the transformer's performance and longevity. For example, areas with high humidity might require additional moisture protection features, while environments exposed to dust or corrosive elements might benefit from enhanced insulation or protective enclosures.

Cooling methods also play a pivotal role in transformer efficiency. Dry type transformers typically use air-cooling systems, making them suitable for installation in areas without flammable liquids. However, the effectiveness of this cooling can depend on ambient temperature and airflow. It's essential to ensure proper ventilation and to consider the heat dissipation capabilities of the installation site.

**Tips:**

- Always evaluate the ambient temperature and humidity level to select a transformer with suitable certifications for those conditions.

- Ensure that installation locations allow for adequate airflow around the transformer to maximize cooling efficiency and performance.

- Consider regular maintenance checks to monitor any environmental impact that may affect operation over time.

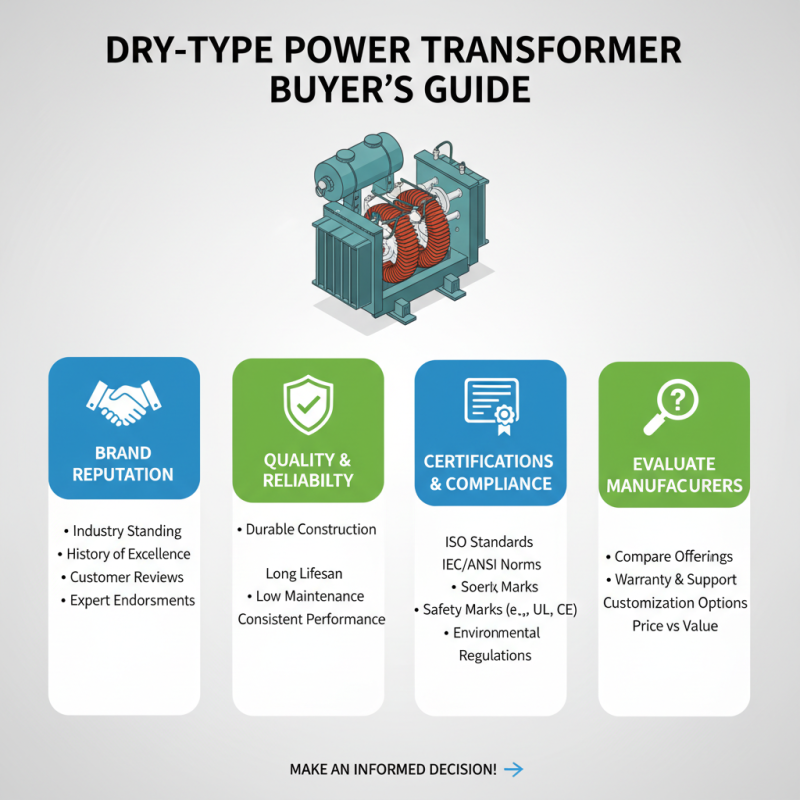

When selecting the best dry type power transformer for your needs, it’s crucial to compare various brands and manufacturers to ensure quality and reliability. Start by evaluating the company’s reputation within the industry. Look for manufacturers that have established a history of excellence in producing durable transformers. Reviews from customers and industry experts can provide valuable insights. Pay attention to certifications and compliance with industry standards, as these can indicate a commitment to safety and performance.

Tips: Always request product specifications and certifications from potential manufacturers. This information can help you assess the specification limits and ensure that the transformer meets your specific operational requirements. It's also wise to consider the availability of after-sales service and warranty options, as these factors significantly impact the long-term performance and maintenance of your transformer.

In addition to manufacturer reputation, consider the technological advancements each company offers. Technological features can greatly enhance transformer efficiency and longevity. Evaluate if they use innovative materials and designs that can withstand environmental stresses. Collaboration with engineers or consultants who specialize in transformers can provide tailored advice that meets your unique operational conditions and needs.