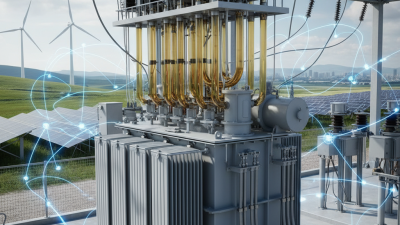

In the realm of electrical engineering, effective transformer testing is crucial for ensuring optimal performance and reliability of power systems. As **Dr. Emily Carter**, a renowned expert in the field of electrical power systems, aptly states, "Thorough transformer testing not only safeguards equipment but also enhances the overall efficiency of electrical networks." This sentiment underscores the significance of implementing rigorous testing protocols to identify potential issues before they escalate into costly failures.

Transformer testing encompasses a variety of methods designed to assess both the physical and operational integrity of transformers. From insulation resistance tests to power factor measurements, each procedure plays a vital role in determining the health of transformers in service. As electrical infrastructure becomes increasingly complex and demand rises, the importance of these tests cannot be overstated. Proper transformer testing practices not only help extend the life of the equipment but also contribute to the safety and reliability of the entire electrical grid.

As the industry evolves, staying abreast of the latest methodologies and technologies in transformer testing will be paramount for engineers and technicians. Emphasizing a proactive approach to maintenance and testing can lead to significant improvements in performance, ensuring that transformers operate at peak efficiency while minimizing the risk of unexpected outages.

Transformer testing is a critical aspect of ensuring optimal performance in electrical systems. The importance of transformer testing cannot be overstated, as it defines the operational reliability and efficiency of power systems across various sectors. According to the IEEE Power and Energy Society, regular testing of transformers can enhance their lifespan by up to 20%, ultimately reducing the total cost of ownership. This is particularly crucial given that transformers are often the most expensive investment in electrical infrastructure, making their reliability paramount.

Moreover, testing allows for the identification of potential issues before they evolve into significant failures. Reports from the International Electrotechnical Commission (IEC) indicate that failures related to insulation breakdown or winding deformation account for approximately 30% of transformer outages. Such preventative measures, combined with techniques like insulation resistance testing and power factor testing, help in maintaining optimal performance and ensuring energy efficiency. With energy losses in transformers typically ranging from 1% to 2% of total electrical output, effective testing can lead to substantial cost savings and improved sustainability in energy consumption.

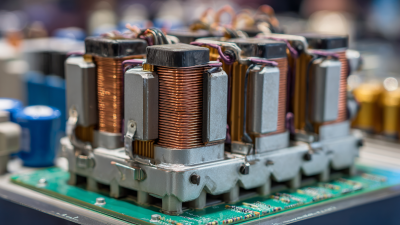

Transformer testing is essential for ensuring optimal performance and reliability in various applications. Different types of transformer tests serve specific purposes, each providing valuable insights into a transformer's functionality and condition. Among these, the insulation resistance test assesses the integrity of insulation materials, which is crucial for preventing electrical failures. Additionally, the power factor test can identify issues related to insulation deterioration, helping to predict potential failures before they occur.

Another critical test is the transformer turns ratio (TTR) test, which evaluates the ratio of the number of turns in the primary winding to the number in the secondary winding. This test is vital for ensuring proper transformer operation and diagnosing winding faults. Furthermore, the sweep frequency response analysis can provide insights into the mechanical condition of the transformer, offering a deeper understanding of internal structural issues.

Tips: Ensure that testing is conducted during scheduled maintenance sessions to avoid unexpected downtime. Regularly updating testing equipment can improve accuracy and reliability in results. Always document test results meticulously to track performance trends over time, enabling proactive maintenance strategies.

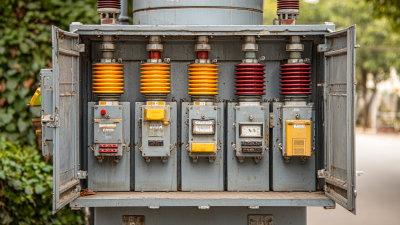

Conducting transformer tests is essential for ensuring the optimal performance and longevity of these critical electrical components. The first step in the testing procedure involves visual inspection. This includes checking for physical damages, leaks, and general wear and tear. Inspecting connections and terminals for corrosion or looseness is also crucial. Following this initial assessment, the technician should proceed to perform insulation resistance testing to gauge the quality of the insulation material and ensure it can withstand high voltage without breakdown.

The next stage of transformer testing is power factor testing, which provides insights into the insulation's condition and helps identify potential issues that could lead to failures. This should be followed by winding resistance testing, where the resistance of the windings is measured to detect any abnormalities. Additionally, short-circuit tests and turns ratio tests may be conducted to verify the transformer's operational integrity. By following this step-by-step procedure, technicians can effectively assess transformer performance, ensuring any necessary maintenance or repairs are completed to maximize efficiency and reliability.

Transformer testing is essential for ensuring optimal performance and longevity of electrical systems. To carry out effective testing, a variety of specialized tools and equipment are utilized, each serving a specific purpose in assessing transformer health. Among the critical tools are insulation resistance testers, which measure the dielectric strength of insulative materials. According to industry standards, a minimum insulation resistance of 1 Megaohm per kilovolt of operating voltage is deemed necessary for safe operation. This tool helps prevent failures caused by insulation breakdown, which is a leading cause of transformer outages.

Another vital instrument in transformer testing is the power factor test set. This equipment evaluates the power factor of the transformer insulator, which can indicate the presence of moisture or contaminants within the insulation system. Industry reports indicate that a power factor reading higher than 0.5% may signal the need for further investigation and potential maintenance. Additionally, thermal imaging cameras are increasingly used to detect hotspots and thermal abnormalities in transformers, allowing for early intervention before more severe damage occurs. The combination of these tools fosters a comprehensive testing regimen, ultimately enhancing the reliability and efficiency of transformer operations.

| Tool/Equipment | Purpose | Key Features | Typical Use Case |

|---|---|---|---|

| Insulation Resistance Tester | Measures the insulation resistance of transformer windings | High voltage output, digital readout | Routine maintenance checks |

| Power Factor Tester | Determines the power factor of insulation systems | Automatic calculations, phase measurement | Testing dielectric losses |

| Transformer Turns Ratio (TTR) Tester | Measures the turns ratio of transformer windings | Precise measurements, portable design | Verification of transformer connections |

| Sweep Frequency Response Analyzer | Analyzes the frequency response for diagnosing transformer conditions | Wide frequency range, detailed spectrum analysis | Assessing internal winding conditions |

| Circuit Analyzer | Evaluates transformer performance in different load conditions | Multi-function capabilities, real-time data | Load testing under operational conditions |

Interpreting test results is crucial for effective transformer management, enabling operators to make informed decisions regarding maintenance and operation. Tests such as insulation resistance, power factor, and frequency response analysis provide insights into the transformer's health and operational efficiency. Proper interpretation of these results allows for the identification of potential issues before they become severe. For instance, a drop in insulation resistance may signal moisture ingress or insulation degradation, prompting timely interventions that can prevent costly outages and extend the lifespan of the equipment.

Furthermore, it's essential to establish baseline performance metrics to accurately assess any deviations observed during testing. By continuously monitoring these test results, operators can implement a predictive maintenance strategy, addressing problems when they are still manageable rather than waiting for failures to occur. Additionally, consistent documentation and analysis of test data over time can reveal trends and patterns, providing valuable information for future upgrades and modifications to optimize transformer performance. Emphasizing ongoing education on result interpretation among technical staff is equally important, ensuring that all team members are equipped to respond effectively to the findings derived from transformer testing.