The energy efficiency of transformers plays a crucial role in the broader context of electrical energy management and sustainability. As technology advances and the demand for energy continues to rise, transformers, which are vital in transmitting and distributing electricity, become ever more significant. According to Dr. Emily Johnson, a leading expert in electrical engineering, “Improving the energy efficiency of transformers not only reduces operational costs but also markedly decreases carbon emissions.” This assertion underscores the imperative need for ongoing research and innovations aimed at enhancing the performance of these devices.

In recent years, the focus on the energy efficiency of transformers has gained momentum, driven by both regulatory pressures and a heightened awareness of environmental issues. Modern transformer designs, materials, and technologies have paved the way for substantial gains in efficiency, yet there remains considerable potential for improvement. By implementing advanced strategies, such as the use of high-efficiency cores and smart monitoring systems, the energy efficiency of transformers can be significantly optimized, resulting in better sustainability outcomes.

Ultimately, as the world moves toward an energy-conscious future, understanding and improving the energy efficiency of transformers will be of paramount importance. Continued collaboration among industry professionals, engineers, and researchers is essential to achieving breakthroughs that can drive the transformation of our energy systems.

Transformers play a crucial role in electrical systems by stepping up and stepping down voltage levels for efficient power transmission and distribution. However, they are also a significant source of energy loss, primarily due to heat generated in their windings and cores. Energy efficiency in transformers is typically evaluated by the efficiency ratio, which compares the output power to the input power, and factors in both no-load and load losses. Higher efficiency not only translates to reduced operational costs but also contributes to a decrease in greenhouse gas emissions, making energy-efficient transformers a vital component in sustainable energy systems.

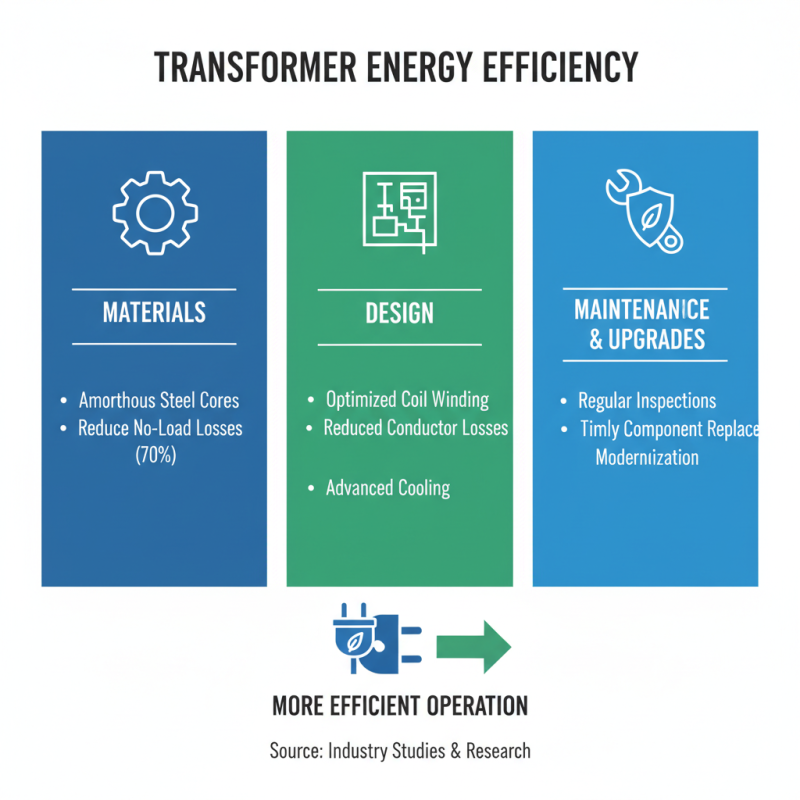

To improve transformer energy efficiency, several strategies can be implemented. One of the most effective methods is the use of high-quality materials for the core and windings, which can significantly reduce magnetic losses and resistive heating. Additionally, employing advanced designs such as amorphous steel cores can help in minimizing energy losses under varying load conditions. Regular maintenance and monitoring of transformer performance can also identify inefficiencies and potential issues that may arise during operation. By focusing on these improvements, organizations can enhance the overall performance of their transformers, leading to substantial energy savings and a more sustainable approach to electricity management.

| Transformer Type | Efficiency (%) | Load Factor (%) | No-Load Loss (W) | Full Load Loss (W) | Improvement Strategies |

|---|---|---|---|---|---|

| Dry-type Transformer | 95.5 | 70 | 100 | 300 | Use high-efficiency core materials |

| Oil-immersed Transformer | 98.2 | 85 | 150 | 600 | Regular maintenance and upgrades |

| Class A Transformer | 97.5 | 75 | 80 | 400 | Optimize load distribution |

| Class B Transformer | 96.0 | 60 | 120 | 500 | Implement smart grid technology |

| Class C Transformer | 94.5 | 50 | 70 | 450 | Upgrade to higher quality insulation |

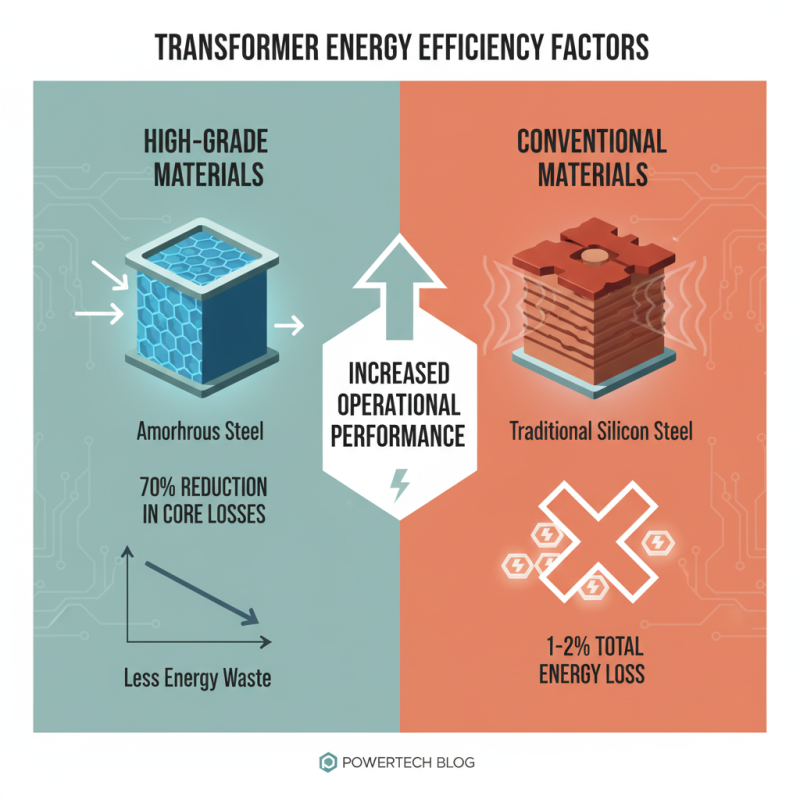

The energy efficiency of transformers is influenced by several critical factors that can significantly affect their operational performance. One of the primary determinants is the quality of the materials used in the transformer construction. High-grade core materials, like amorphous steel, can reduce core losses by up to 70% compared to conventional materials. This reduction is vital, as core losses account for a considerable portion of energy waste in transformers, estimated to be approximately 1-2% of total energy losses in typical applications.

Another crucial factor impacting transformer energy efficiency is load management. Transformers are designed to operate at optimal efficiency at specific load levels, typically around 75%-80% of their capacity. Operating outside these load ranges can lead to increased losses, with no-load losses remaining constant and load losses rising with increased current. Additionally, the maintenance of transformers plays a significant role; regular inspection and timely replacement of aging components can minimize energy losses due to inefficiencies that gradually build up over time. According to the U.S. Department of Energy, implementing such best practices can enhance energy savings by anywhere from 5% to 10%, making them essential for improving overall transformer efficiency.

When it comes to improving the energy efficiency of transformers, a multi-faceted approach is essential. Strategies can include enhancing core materials, optimizing design, and implementing advanced manufacturing techniques. For instance, using amorphous steel for transformer cores can reduce no-load losses by approximately 70% compared to traditional silicon steel, as reported by various industry studies. Additionally, regular maintenance and timely upgrades can ensure transformers operate at peak efficiency, reducing energy waste.

Tip: Regularly monitor your transformer's operational performance. Utilizing smart sensors can help identify inefficiencies or faults in real time, allowing for quicker intervention and maintenance, which can contribute significantly to energy savings.

Another strategy involves minimizing the overall size and weight of transformers without compromising performance. This can be achieved through the use of high-efficiency winding techniques and optimized coil designs, which not only enhance energy efficiency but can also reduce material and manufacturing costs. According to the Department of Energy, implementing such design improvements could lead to a reduction in energy costs by up to 10%, translating into substantial savings over the lifespan of the transformer.

Tip: Consider retrofitting older transformers with modern, high-efficiency components. Upgrading parts like bushings, tap changers, and cooling systems can significantly extend the lifespan of your transformers, improving overall energy efficiency.

Technological innovations in transformer design play a crucial role in enhancing energy efficiency, which is vital for sustainable power distribution. One significant advancement is the development of amorphous steel core transformers. These transformers utilize materials with lower magnetic losses, significantly reducing energy wastage. By minimizing hysteresis and eddy current losses, amorphous core transformers can achieve efficiency gains of up to 98%, making them an attractive option for both utility and industrial applications.

Another noteworthy innovation is the integration of advanced cooling technologies. Conventional transformers rely on oil or air cooling, which can limit their efficiency under heavy loads. New designs incorporate innovative cooling methods such as forced air cooling or hybrid systems that combine air and liquid cooling, allowing for better thermal management and reduced operational losses. Additionally, smart transformer technology enables real-time monitoring of performance and load conditions. This data-driven approach allows for proactive maintenance and optimization of energy use, further enhancing the overall efficiency and reliability of transformer systems.

Measuring and monitoring transformer efficiency is crucial for optimizing energy consumption in electrical systems. The efficiency of a transformer can be determined by calculating its output power as a percentage of its input power. This involves taking precise measurements of voltage and current on both the primary and secondary sides under various loading conditions. Regular testing helps identify any deviations in performance, which could indicate issues such as winding resistance, core losses, or insulation problems.

To monitor transformer efficiency effectively, advanced diagnostic tools and technologies can be employed. These may include power analyzers that provide real-time data on energy losses and performance metrics. Additionally, ongoing maintenance checks equip operators with insights into how environmental factors, such as temperature and humidity, affect efficiency. Implementing a robust monitoring system not only aids in maintaining optimal operation but also facilitates necessary adjustments or upgrades to enhance overall efficiency and reduce energy consumption in the long run.