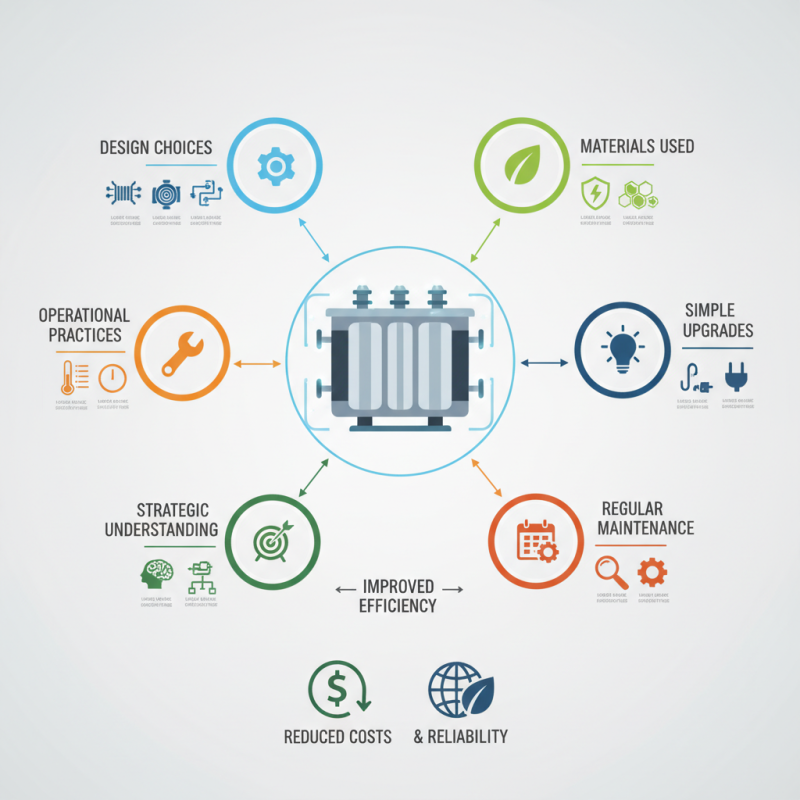

Improving electrical transformer efficiency is crucial for optimal performance in various applications. Transformers play a vital role in power distribution. Their efficiency impacts energy loss and operational costs. Therefore, understanding how to enhance their performance is essential.

Many factors affect electrical transformer efficiency. These include design choices, materials used, and operational practices. Simple upgrades can lead to significant efficiency gains. For instance, better insulation materials can reduce energy losses. Yet, some approaches may require reconsideration of existing systems.

Addressing electrical transformer efficiency is not only technical. It involves a strategic understanding of operational needs. Organizations often overlook regular maintenance, impacting performance. Reflection on these practices can lead to improved outcomes and reduced costs. Each step taken toward better efficiency can contribute to sustainability and reliability in energy systems.

Understanding electrical transformer efficiency is crucial for maximizing performance. Efficiency refers to how well a transformer converts input power into output power. High efficiency means less energy loss, which is vital for reducing operational costs and environmental impact. Typically, transformers operate at 95% to 99% efficiency. However, achieving this ideal efficiency involves addressing various factors.

One common issue is heat loss. This occurs due to resistance in the windings and core losses. Regular maintenance and monitoring can help identify problems early. For instance, using high-quality materials can improve conductivity. Additionally, proper sizing of transformers is essential. Oversized or undersized transformers can lead to inefficiencies. Finding the right balance is often challenging.

Another aspect to consider is load management. Transformers are most efficient when operating near their rated capacity. Operating far below or above this point causes unnecessary energy loss. Understanding load patterns can help optimize usage. Regular audits of energy consumption provide insights into transformer performance. Reflecting on these areas can lead to better decisions. Not all solutions are straightforward, but striving for improvement matters.

Transformer efficiency is crucial for reducing energy losses. Many factors influence how well a transformer performs. Design plays a vital role. The shape, core material, and winding configurations must be optimized. For instance, using high-quality magnetic materials can enhance performance. However, this may increase costs. Balancing quality and expense is often challenging.

Materials also significantly affect efficiency. For example, copper winding is commonly preferred over aluminum. Copper has better conductivity, thus minimizing losses. However, it is more expensive. There’s a trade-off between initial investment and long-term savings. Choosing the right insulator can also improve thermal performance and durability. Yet, many may overlook this factor during the design process.

It's essential to consider operational conditions. An overloaded transformer can lead to overheating, decreasing overall efficiency. Regular maintenance can identify potential issues early. Despite having the right design and materials, real-world application often differs. Monitoring performance can reveal unexpected inefficiencies and areas for improvement. Analyzing these elements helps in optimizing transformer performance.

Transformer efficiency is crucial for optimal performance. One effective way to enhance this efficiency is through advanced cooling techniques. These techniques help manage the heat generated in transformers. Excessive heat can lead to reduced efficiency and potential failures.

Implementing cooling systems, such as liquid cooling, can significantly improve heat dissipation. This method uses specialized fluids to absorb heat effectively. However, selecting the right coolant is vital. Not all fluids perform equally well. Additionally, maintenance of these systems is critical. Neglecting maintenance can lead to inefficiencies.

Air cooling is another option, but it may not be sufficient for large transformers. It can sometimes compromise performance under heavy loads. Enhanced ventilation can help, but it has its limitations. It is essential to monitor temperature levels continuously. Regular assessments can help identify potential issues early, fostering a more reliable system.

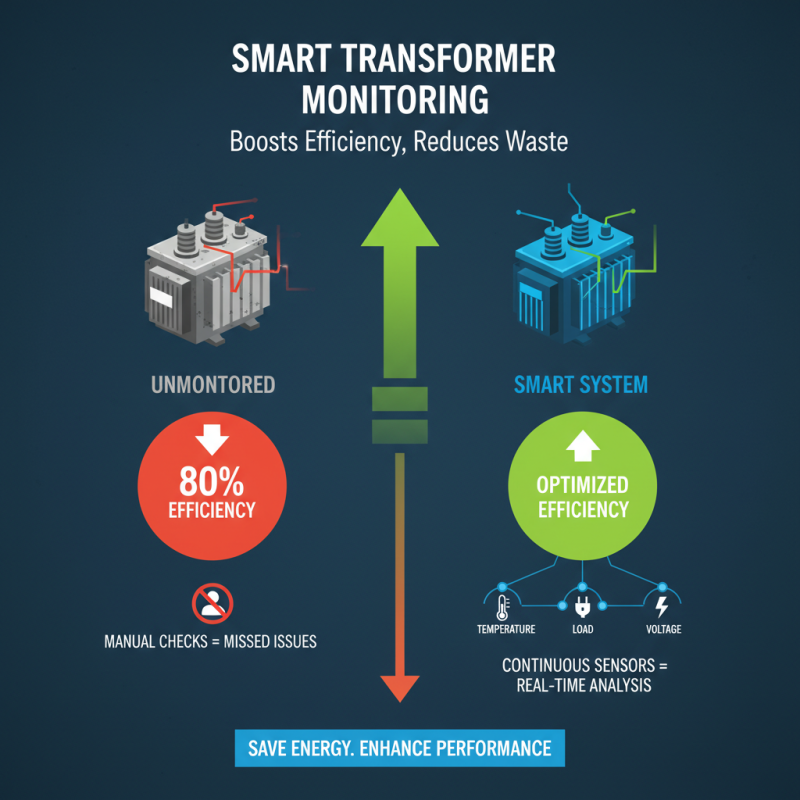

Real-time efficiency analysis through smart monitoring systems can significantly enhance transformer performance. Reports indicate that unmonitored transformers can operate at efficiency levels as low as 80%, leading to energy wastage. Smart systems utilize sensors to track performance metrics continuously. These metrics include temperature, load, and voltage parameters, identifying inefficiencies that manual checks might overlook.

Data from industry studies suggests that implementing such systems can boost efficiency by 10-15%. This improvement translates to reduced operational costs and prolonged equipment life. However, many organizations lack the expertise to interpret the data effectively. Regular audits can provide insights, but reliance on data alone may miss underlying issues.

Implementing smart monitoring isn't a one-size-fits-all solution. Poor installation or incorrect calibration can lead to misleading results. Companies often struggle to strike a balance between new technology and existing infrastructure. The integration process must be approached systematically, allowing for adjustments based on operational realities. Careful planning and ongoing evaluation can help address these challenges effectively.

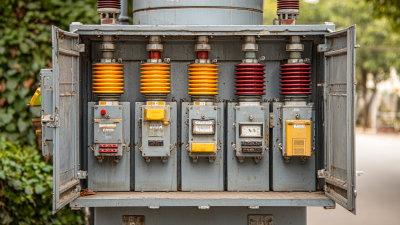

Maintaining electrical transformers is crucial for their efficiency. Regular inspections can identify potential issues early. Inspect the insulation for signs of wear or damage. This simple step can prevent major failures down the road. Checking connections also ensures optimal performance. Loose or corroded connections can lead to energy losses.

Additionally, monitoring temperatures is essential. High operating temperatures often indicate problems. Use thermal imaging cameras for quick assessments. Cleanliness matters too. Dust accumulation can cause overheating. Making cleaning part of routine maintenance helps preserve transformer life.

Record keeping is vital for tracking performance. Documenting maintenance activities allows for better decision-making. Neglecting this aspect can lead to missed patterns. Addressing minor issues now can save significant costs later. Keep an eye on oil levels, as low levels can indicate leaks. Consistent maintenance practices promote reliability, but they require discipline and ongoing attention.

This bar chart illustrates the efficiency improvements of electrical transformers with regular maintenance practices over a period of time. Each category represents a different maintenance practice and its corresponding efficiency percentage.