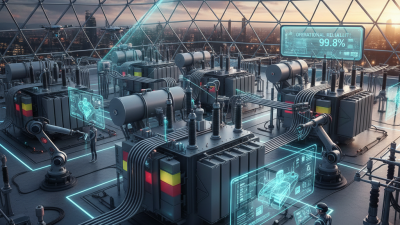

In the evolving landscape of the electrical power industry, ensuring the safety and reliability of power transformers has never been more critical. According to a report by the International Energy Agency (IEA), transformer failures can result in significant economic losses, averaging up to $10 million per incident, highlighting the importance of effective power transformer testing. With the increasing complexity of electrical systems and the demand for uninterrupted power supply, advanced testing methods have become essential for utilities and manufacturers alike.

Dr. John Smith, a renowned expert in electrical engineering and a leading voice in the field of power transformer testing, emphasizes the necessity of rigorous testing protocols: “The reliability of power transformers is paramount for grid stability and energy distribution—only thorough testing can ensure their optimal performance.” This assertion underscores the fundamental role that testing plays not only in safeguarding equipment but also in enhancing overall system efficiency.

As the industry continues to innovate, understanding the latest testing methodologies is crucial for enhancing transformer performance and reliability. This article will explore the top five power transformer testing methods that can significantly improve safety and operational integrity, ensuring that transformers meet the demands of modern electrical grids.

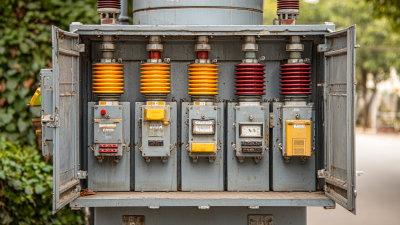

Power transformer testing is a vital process that ensures the safety and reliability of electrical distribution systems. With the ongoing advancements in technology, testing methods have become more sophisticated, thus enhancing the integrity of transformers. According to recent studies, the market for electrical testing services is projected to grow robustly, emphasizing the increasing demand for transformer testing. One key technique involves the use of insulating oil tests, which play a crucial role in identifying the condition and performance of transformers. This method aids in preventing failures that could lead to catastrophic outcomes, especially in regions prone to natural disasters.

Tips: Regular testing can significantly prolong the lifespan of transformers and minimize downtime. Ensure that the testing adheres to the latest standards and employs state-of-the-art technology to guarantee accurate results.

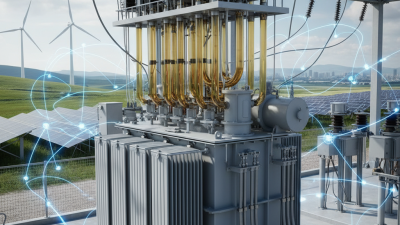

Moreover, the expansion of transformer plants, such as the recent developments in Canada and Thailand, highlights the industry's commitment to enhancing both the supply chain resilience and safety measures. Understanding the importance of power transformer testing not only aids in operational efficiency but also strengthens safety protocols essential for protecting infrastructure and personnel.

Tips: Collaborate with certified professionals to perform regular maintenance and testing. Staying updated on regulatory changes can also help maintain compliance and foster a safer electrical environment.

Power transformers are vital components in the electrical grid, ensuring the delivery of electricity is stable and reliable. To maintain their performance, employing essential testing methods is crucial. A proactive and holistic approach to testing can enhance transformer reliability, thus reducing potential outages and maintenance costs. Techniques such as Dissolved Gas Analysis (DGA) can accurately diagnose transformer health, highlighting any issues before they escalate.

Tips for Effective Transformer Testing:

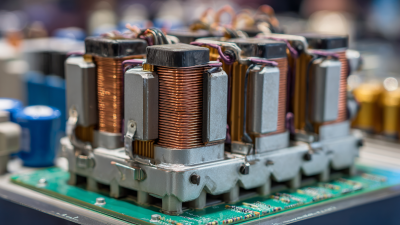

Insulation resistance testing is a critical procedure in ensuring the safety and reliability of power transformers. This method involves applying a high DC voltage to the insulation system and measuring the resistance of the insulation. A high resistance value indicates that the insulation is effective, while lower values may suggest potential issues such as moisture ingress or deterioration of materials. Conducting this test periodically can help detect weaknesses before they lead to catastrophic failures.

To perform insulation resistance testing, first ensure that the transformer is isolated from supply voltage. Next, use a megohmmeter to apply the specified test voltage, typically ranging from 250V to 5kV, depending on the transformer specifications. Monitor the resistance readings closely, paying special attention to any significant drops from previous tests. After obtaining stable readings, record them for future reference and comparison. It is also essential to understand the environmental conditions during testing, as temperature and humidity can affect the results. Regular insulation resistance assessments not only enhance the safety of transformer operations but also extend equipment lifespan by identifying insulation failures early on.

| Testing Method | Description | Frequency | Key Benefits |

|---|---|---|---|

| Insulation Resistance Testing | Measures the resistance of electrical insulation to determine its condition. | Annually | Identifies insulation degradation, enhances safety. |

| Transformer Turn Ratio Testing | Verifies the turns ratio of windings to ensure proper transformation. | Every 5 years | Detects winding shorts or opens, confirms transformer rating. |

| Power Factor Testing | Assesses the power factor of insulation to detect moisture and contamination. | Every 3 years | Offers insight into insulation health and improves maintenance. |

| Sweep Frequency Response Analysis | Analyzes the frequency response of transformers to diagnose their mechanical integrity. | As needed | Identifies winding movement, helps prevent failures. |

| Dissipation Factor Testing | Quantifies energy loss in insulating materials under an electric field. | Annually | Monitors insulation condition, ensures operational reliability. |

Power factor testing techniques play a vital role in evaluating transformer performance, particularly in the context of modern electric power systems where efficiency and reliability are paramount. By assessing the power factor, engineers can identify energy losses and potential operational issues in transformers, ensuring optimal performance. This method is crucial not only for maintaining operational integrity but also for enhancing the safety of electrical systems, especially as transformers become integral to the integration of renewable energy sources.

As the demand for reliable power quality increases, the evaluation of transformer conditions through non-invasive measurement techniques has gained prominence. Utilizing advanced algorithms for condition assessment allows for real-time monitoring and diagnostics, which are essential for preemptively identifying faults. Such proactive measures not only improve the longevity and efficiency of transformers but also significantly contribute to maintaining stable power quality across distribution networks—an increasingly critical factor as electronic devices are integrated into modern economies.

Sweep Frequency Response Analysis (SFRA) has emerged as an essential tool for monitoring the health of power transformers, particularly in the face of increasing mechanical and electrical stresses that these critical components endure. According to industry estimates, nearly 12-15% of distribution transformers fail annually, often due to undetected winding defects. The incorporation of SFRA allows for the identification of these winding defects through precise measurements of frequency response characteristics, which reveal insight into the diagnostic status of the winding insulation and its geometric configuration.

Recent advancements in data visualization techniques further enhance the efficacy of SFRA, making it possible for engineers to interpret complex results more intuitively. With tools such as new SFRA software, technicians can swiftly align data and identify failure trends, thus enabling proactive maintenance strategies. This is vital in modern power systems, where effective condition monitoring is imperative not only for reducing downtime but also for ensuring national energy security, as even minor transformer failures can lead to cascading blackouts across interconnected power grids. These proactive measures not only save costs in the long run but also improve reliability in an increasingly distributed energy resource landscape.